Is Alloy Wheel Spraying a Good Option for Protecting Your Wheels from Corrosion?

As vehicles become more sophisticated, so too do the methods used to protect and maintain their components. One such method is alloy wheel spraying, a technique that has been gaining popularity among car owners and enthusiasts alike. But is it truly a good option for protecting your wheels from corrosion?

Understanding Alloy Wheel Spraying

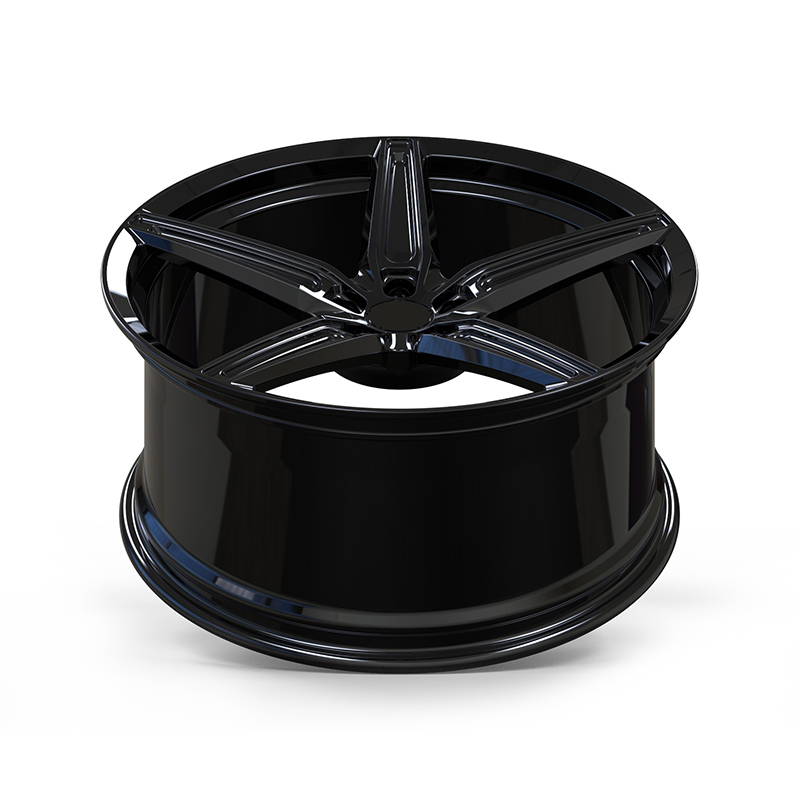

Alloy wheel spraying is a process that involves applying a protective coating to the surface of the wheels. This coating is designed to shield the alloy from various environmental factors that can cause corrosion, such as moisture, salt, and other contaminants. The process is not only beneficial for black alloy wheels but also for classic alloy wheels, which often have a more intricate design that can be susceptible to damage.

The Benefits of Alloy Wheel Spraying

1. Protection Against Corrosion: The primary advantage of alloy wheel spraying is its ability to protect the wheels from corrosion. The coating acts as a barrier, preventing moisture and other corrosive substances from coming into contact with the alloy.

2. Enhanced Aesthetics: For black alloy wheels, the spraying process can enhance their appearance, providing a glossy finish that is both visually appealing and resistant to scratches and chips.

3. Longevity: Classic alloy wheels, with their intricate designs, can benefit from the added durability that spraying provides. The coating can extend the life of the wheels, reducing the need for frequent replacements.

4. Customization: Alloy wheel spraying allows for a high degree of customization. Car owners can choose from a variety of colors and finishes, ensuring that their wheels match the overall aesthetic of their vehicle.

5. Cost-Effectiveness: Compared to other methods of wheel protection, such as plating or painting, alloy wheel spraying is often more cost-effective. It provides a high-quality finish without the need for extensive labor or materials.

Considerations for Alloy Wheel Spraying

While the benefits of alloy wheel spraying are clear, there are also some considerations to keep in mind:

1. Quality of the Coating: The effectiveness of the spraying process depends largely on the quality of the coating used. It's important to choose a reputable service provider that uses high-quality materials.

2. Maintenance: Although alloy wheel spraying provides a protective layer, it still requires proper maintenance to ensure its longevity. Regular cleaning and inspection can help maintain the integrity of the coating.

3. Compatibility: Not all coatings are compatible with all types of alloy wheels. It's important to ensure that the chosen coating is suitable for the specific alloy composition of the wheels.

4. Environmental Impact: The process of alloy wheel spraying can have an environmental impact, particularly if harmful chemicals are used in the coating. It's important to consider the environmental footprint of the spraying process.

5. Professional Application: To achieve results, alloy wheel spraying should be performed by a professional. This ensures that the coating is applied evenly and effectively, providing the improve level of protection.

The alloy wheel spraying is indeed a good option for protecting your wheels from corrosion. Whether you own black alloy wheels or classic alloy wheels, the process offers a range of benefits that can enhance the performance and appearance of your vehicle. However, it's important to weigh the considerations and choose a reputable service provider to ensure results. With the right approach, alloy wheel spraying can be a valuable investment in the longevity and aesthetics of your vehicle's wheels.

If you have any questions, please fill out the contact form at the bottom of the page and contact us.